TM 1-1520-265-23

5-32

Change 2

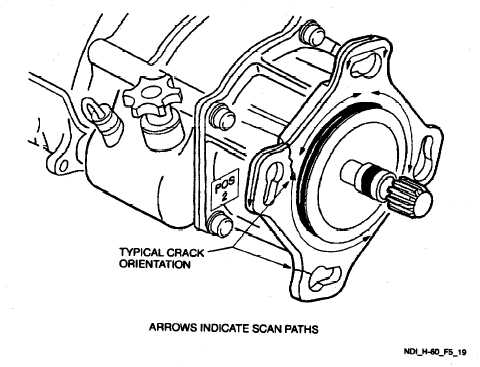

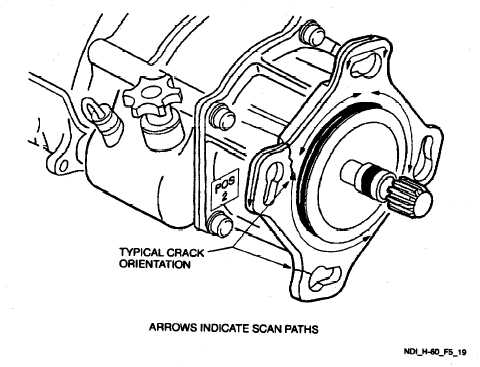

Figure 5-19. Starter Flange

NOTE

Either probe identified in paragraph 5.19.3.1 may be used depending primarily on the

ease of accessibility and user friendliness. If the probes are changed, steps

5.19.3.5b.(1), (2), and (3) shall be repeated each time a change is made.

5.20 ENGINE SHROUD (PT).

5.20.1 Description (Figure 5-1, Index No. 20). The engine shroud is mounted on top of the engine.

5.20.2 Defects. This inspection is used to verify crack indications found visually. No cracks are

allowed.

5.20.3 Primary Method. Fluorescent Penetrant.

5.20.3.1 NDI Equipment and Materials. (Refer to Appendix B.) Inspection equipment is listed in

Table 1-7. AMS 2644 level 3 penetrant materials shall be selected from the approved list in Table

1-8. Parts requiring flourescent penetrant inspection shall be cleaned prior to inspection with

n--Propyl Bromide (vapor degreasing only)(Table 1--8), DS--108 (Table 1--8), Electron (Table 1--8),

Positron (Table 1--8). DS--108, Electron, Positron must be followed by an acetone (Table 1--8) rinse

or wipe: or drying until there is no visible solvent residue left on parts.

5.20.3.2 Preparation of Helicopter. The helicopter shall be prepared for safe ground maintenance.

A partial inspection for cause (visual indications, sites of mechanical damage, corrosion, etc.) may

be performed on all exposed surfaces of the installed part using this procedure. If required, the

shroud shall be removed in accordance with the applicable technical manuals listed in Table 1-1.