TM 1-6625-724-13&P

0075 00

0075 00-9

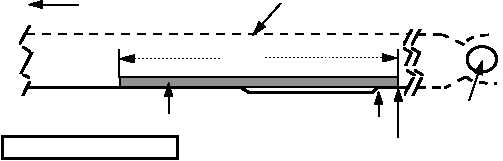

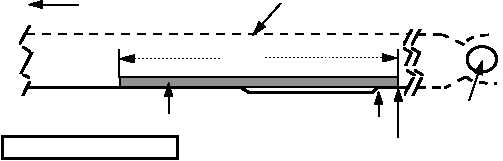

6 feet

Reflective Tape

Hub-end of Trim Tab

6 Inches Inboard of Trim Tab End

Blade Tip

Blade Leading Edge

DRAWING NOT TO SCALE

Hub

5017-005 A

6A. FORWARD ROTOR BLADES

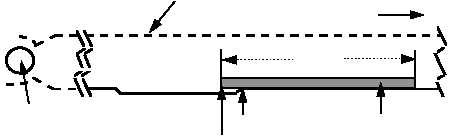

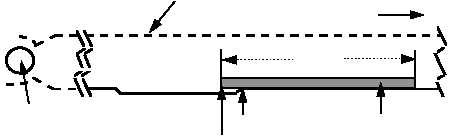

6 feet

Reflective Tape

Tip-end of Trim Tab

6 Inches Inboard of Trim Tab End

Blade Tip

Blade Leading Edge

Hub

DRAWING NOT TO SCALE

5017-006 A

6B. AFT ROTOR BLADES

Figure 6. Placement of Reflective Tape on Forward and Aft Rotor Blades

PROCEDURE 6: COMBINER TRANSMISSION OIL COOLING FAN SENSORS INSTALLATION

(50 HOUR CHECK ONLY)

a. Complete procedure 2.

b. Gain access to the combiner transmission cooling fan area, see figure 7.

c. Remove nuts from combiner transmission oil cooling fan mounting flange studs at the 5:00 and 8:30 clock

positions.

d. Mount an accelerometer mounting bracket (29339500) to each of the studs with the nuts provided. See figure

7.

NOTE

When mounting accelerometers, make certain that they

are in line with the corresponding axis (lateral and

longitudinal). See figure 7 top view.

e. Install accelerometer (28110900), accelerometer 1 (ACC1), in the lateral axis on the mounting bracket

(29339500) that is on the stud at 5 o’clock. The nose of the aircraft is at 12 o’clock position.

f. Install accelerometer (28110900), accelerometer 3 (ACC3), in the longitudinal axis on the mounting bracket that

is on the stud at the 8:30 clock position.

g. Connect 50-ft accelerometer cable assemblies (29105600) to the lateral accelerometer (ACC1), and to the

longitudinal accelerometer (ACC3).

h. Run the cable from the longitudinal accelerometer around the back of the oil cooler.

i. Identify each accelerometer cable (ACC1, and ACC3) and feed the cables through the lightening hole at station

482 on the right side.

j. Tie-wrap the accelerometer cables away from the sync shaft and engine drive shaft and route the cables to the

DAU.